Need a 3D printer on a tight budget? So does every other new entrepreneur and startup. You’re just not likely to find very many of them admitting it in public.

Most of the best 3D printers under $1000 don’t want to be listed in the first place. Some will charge you $300+ for their advice alone – and then only put you on to their competitors’ products.

You need help with your choices. Luckily, you have it here. We figure there’s no point pretending that all 3D printers under $1000 are better than all others. After all, if they were, they’d cost more, right? We’ll guide you through the maze of available options and help you understand what each is designed to do. For the money you’re after, there really is something out there for everybody!

Overview Of The Best 3D Printers Under $1000:

Voxelab Aquila 3D Printer X2

The Voxelab Aquila, released in July 2021, pushed its predecessor the Anycubic Mega Zero and famous Creality Ender 3 to second place. This goes to show just how impressive this little budget printer is.

Voxelab is the budget sub-brand of 3D printing giant Flashforge, but it would be misleading to describe it as an underdog because this company has many hidden strengths.

The Voxelab Aquila retails for under $200, making it a viable option for any shopper looking to stay within budget. Furthermore, it can be purchased for around $150, making it a great value option. It checks all the boxes on your must-have list—it’s affordable, reliable and produces high quality prints. Check out their website to get more information!

Surprisingly, its interface is straightforward and easy to use. The large icons make it clear what each button does without any guesswork. The VoxelMaker slicing software, a revamped version of Flashforge’s Flashprint program that comes standard with the Creator Pro 3D Printer, provides enough functionality for beginners to get their feet wet.

For advanced users, full compatibility with any G-code generating software gives space to grow as a printer. Many reviewers fantastic print quality with little effort. The textured carborundum glass bed works particularly well with ABS and PLA, gripping when hot but releasing prints without trouble once cool—although PETG should be printed onto a glue stick for reliable adhesion.

The Aquila handles overhangs surprisingly well for such an affordable machine, and part cooling is particularly good on it— all in all, this printer offers significant improvements from its predecessor: the Ender 3.

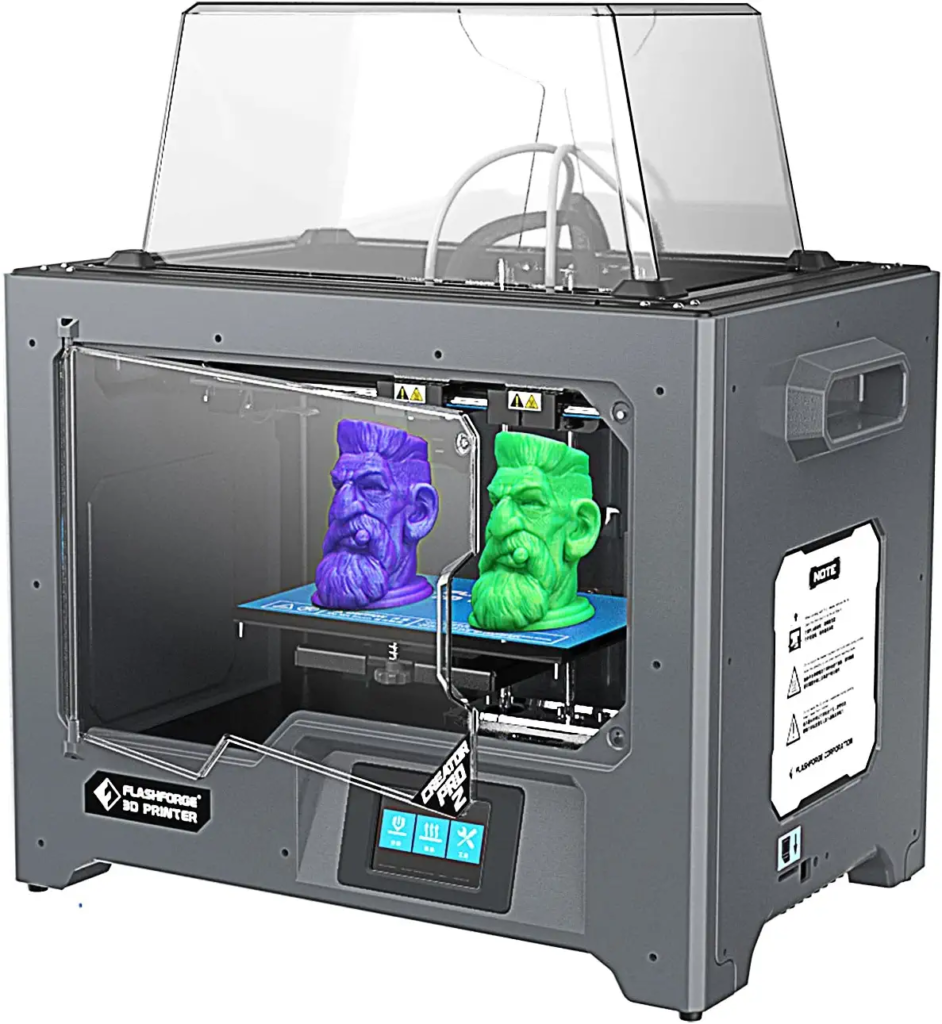

FLASHFORGE Creator Pro 2 Fully Enclosed 3D Printer

The Flashforge Creator Pro 2 is an updated version of the original, which allows users to add dual extrusion capabilities without drastically increasing their budget.

Most of us would pay double for the ability to juggle different materials, colors and support structures. And we’d be willing go so far as paying triple if that meant being able to print fancy dual objects in one pass!

The Flashforge Creator Pro 2 is a well-designed printer, with an accurate extruder that produces seamless transitions between different materials and colors.

The print quality remains consistent, regardless of whether you’re using PLA, HIPS HVA or ABS filament—the fully enclosed chamber and 120°C heated bed cause heat-sensitive material to adhere especially well.

Furthermore, the build volume feels a bit cramped, and the reduced size compared to some competitive models can be an issue if you are printing large objects. However, due to its dual extrusion system—called IDEX (Integrated Dual-extrusion) technology—the printer allows for two different materials at once without compromising print quality or wasting any filament.

One small complaint that deserves mention is the FlashForge Creator Pro 2’s dependence on its own limited interface, FlashPrint. While FlashPrint is a competent manufacturer slicer, we always feel limited when using it because of the lack of advanced features offered by other third-party slicing programs like Cura.

The Flashforge Creator Pro 2 is a worthwhile purchase for makers who have outgrown their starter printers or are new to the 3D printing market.

R QIDI TECHNOLOGY 3D Printer

The Qidi Tech X-Plus is one of the most affordable 3D printers, but it delivers results comparable to those produced by high-end models.

The printer may not have the sleek appeal of some competitors, but it works with a wider variety of materials and is still worth considering.

The Qidi Tech X-Plus’ dual interchangeable extruder system is responsible for much of the printer’s versatility. Not only can you print with PLA, PETG and TPU filaments—materials that are heat-sensitive like ABS or nylon—but each extruder can be fine tuned to match its material

A double-sided, reversible heated bed offers two levels of adhesion—low temperature for fragile filament or high temp for strong materials.

The processing chamber is designed to accommodate different materials: with its cover closed, it maintains stable temperatures for ABS; and without the covers, PLA has all the airflow needed for reliable prints.

The Qidi Tech X-Plus boasts a color touch screen, Wi-Fi connectivity, dual Z axis design and air filtration system. It also has well guided assisted bed leveling functionality as well at a maximum printing size of 270 x 200 x 200 mm for medium to large parts— making it an excellent candidate for professional 3D printing.

These features make the X-Plus series from Qidi Tech an excellent choice for home or small office users who want to print high quality photos without spending a fortune.

Creality 3D Printer Ender 3 S1

The Ender 3 S1 may look very similar to its predecessors, but Creality has made significant modifications. In the Ender 3 S1, they’ve taken a step up from previous machines in terms of quality and performance.

The Z-axis movement is driven by dual stepper motors, the print bed is made of flexible and durable metal coated with a protective sheet that prevents warping, and the lightweight print head introduces two reducer gears which directly feed filament to the hot end beneath.

Its larger build volume makes the S1 a leading pick for 3D printing enthusiasts, but its Sprite extruder (which allows you to load filament quickly and easily) and strong gearing (reducing clogs/under-extrusion issues) is what really sets it apart from other models.

The Sprite comes with a CR-Touch auto-bed leveling probe, which allows the printer to create a virtual map of variances in the surface–in short, this process eliminates guesswork and helps you attain perfect first layers.

The addition of a full-size SD card in this one of the best 3d printers under $1000 for data transfer, tool drawer and belt tensioners makes this one of the best updates on an already popular 3D printer.

Unfortunately, the Ender 3 S1 Pro doesn’t offer the self-diagnostic smarts or maker punk looks of its more advanced brother, but it does print hotter than the vanilla S1. If you’re looking for a fuss-free printing experience in an affordable package, this is your best bet.

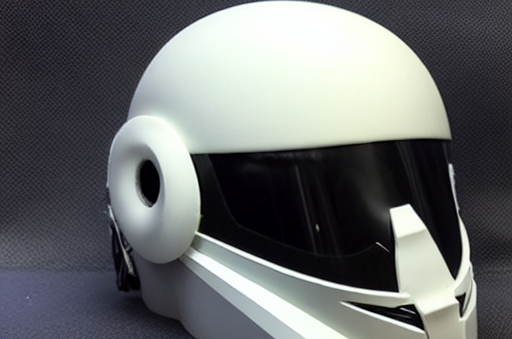

ANYCUBIC Photon Mono X 6K Resin 3D Printer

The AnyCubic Photon Mono X 6K overcomes one of the main drawbacks of resin printing by combining an exceptionally detailed 6K LCD with an incredibly large build volume—without sacrificing print quality.

The AnyCubic Photon Mono X 6K offers a compelling combination of high-quality printing and affordability that no other 3D printer in its class can match.

The 9.25-inch 6K monochrome LCD delivers ultra-slim print resolution at 34 microns, providing a pixel resolution of 5760 x 3600 pixels.

On the build plate, AnyCubic Photon Mono X 6K offers 192 x 120 x 245 mm of printable area for creating decently-sized parts.

The AnyCubic Photon Mono X 6K is a speedy printer, with the ability to cure resin at up to 80 mm/h. In other words, it’s no slouch when it comes time for you to produce parts.

AnyCubic has earned a reputation for building resin 3D printers that produce high-quality prints.

The Photon Mono X 6K, like its Photon siblings, is an exceptional printer. It produces beautiful prints with a near flawless finish and delivers superb quality parts—all at an incredible price point! And much like the other AnyCubic machines we’ve reviewed before this one, it’s also well-built and extremely user friendly—even though this particular model lacks automatic bed leveling during printing.

For makers looking to print large, high-fidelity prints, the AnyCubic Photon Mono X 6K is a wise purchase: whether you’re into model making, tabletop gaming or prototyping—this printer will deliver.

Best 3D Printers under $1000 – Buying Guide

3D printing is a technology that allows you to create your own objects using 3D modeling software. It can be used to make many types of things, such as jewelry and furniture. There are several different types of printers available today, each with their own pros and cons. We’re going to cover some basics about choosing the right printer for your needs before we dive deeper into SLA vs FDM 3D printers and what kind would be best for your budget or needs.

Let’s figure out how you can buy the Best 3D Printers under $1000 with the best tactics and practices.

First step: SLA or FDM?

It’s important to understand the differences between SLA and FDM. Both types of 3D printing are based on the same technology, but they are used for different things. SLA stands for Stereolithography, which was invented by Charles Hull in 1988. It uses a liquid resin to build up layers of plastic filament that harden when they’re exposed to UV light (which is typically provided by an ultraviolet lamp).

FDM stands for fused deposition modeling—it’s another way of doing 3D printing using polymer filaments instead of thin layers like those created with SLA technology

Stereolithography (SLA) printers

3D printers that use stereolithography (SLA) are among the most common and widely used in the industry. SLA printers utilize a UV laser to solidify resin, creating objects with very fine details. The resin is cured by the laser into a solid object, which can then be sanded and polished.

The process begins with UV light shining onto a liquid-like substance called polyester composite, which contains melted resins and solvents that absorb it before they’re exposed to ultraviolet rays from an LED light source above them; this causes them all together to bond together as one big blob of plastic-like material called “sintering” (which sounds super cool).

Once this happens repeatedly over time—and depending on how much exposure each layer gets—you’ll end up with something like what would happen if someone took their favorite Disney princess doll out of its box right after unwrapping her: no seams between pieces!

Fused deposition modeling (FDM) printers

Fused deposition modeling (FDM) printers are the most common type of 3D printer. This method uses a hot plastic filament to build objects layer by layer, much like a standard inkjet printer.

The primary benefit of using FDM is its affordability—most models can be purchased for under $1,000 and have build volumes as large as 100 x 100 x 100 millimeters or more.

The other major advantage to an FDM printer is that they tend to be more reliable than other types of 3D printers because they don’t require any special software or hardware configuration on your computer before you start printing your design files; simply load them up into the machine and let it go!

What’s the right speed and resolution for my print job?

Resolution is the size of the print, measured in microns. The higher the resolution, the smaller your object will be and vice versa. Resolution also affects how many layers you’ll need to print in order to make your design—if you have a small model with lots of detail but only 200 microns per layer (like a skull), then printing at 25% resolution would be enough to create an accurate 3D model of that skull; however if it were 200 microns thick instead of 50 layers thin like most people do when they’re starting out with their first prints!

Speed refers to how quickly a printer can move its nozzle around during each layer being printed; this depends on whether or not there’s any friction between parts being joined together by ABS plastic filament which prevents them from sliding smoothly over each other as they go through their respective heating stages during molding/casting processes like those used by 3D printers today.”

How big a printer do I need?

The size of your 3D printer will depend on the size of parts you want to print. If you’re trying to make small amounts of models, then a smaller machine might be sufficient. However, if you’re looking at printing large models or making multiple copies at once, then a larger printer will likely be more useful.

If possible and affordable (which it usually isn’t), consider getting one that can hold several different sized parts on its bed at once so they won’t require assembly before being printed out in one go. This way no matter how many times you want something printed out from scratch each time someone new comes into town who wants their very own version!

How much does a 3D printer cost?

The cost of a 3D printer can vary widely, but the most expensive ones are typically in the $4,000 to $10,000 range. The price you pay will depend on factors such as features and size. For example, a smaller model may be cheaper than a larger one that has more features—and vice versa!

The speed of printing also plays an important role in determining how much your 3D printer costs: if you’re looking to make large prints quickly (like prototypes), then you’ll need something with high-speed capabilities; however if it’s just used for personal use (maybe even hobbyist purposes), then these things aren’t necessary because they slow down production time so much that it negates any potential savings associated with buying them anyway…

What about 3D printer software?

3D printer software is the operating system for your 3D printer. It’s what allows you to design and print objects, or parts of models.

You can use it to create anything from simple designs that involve only a few shapes, all the way up to complex models with hundreds of parts and subassemblies.

Conclusion

Choosing the right 3D printer for your job is a big decision, but it’s one that will pay off in the long run. With the right model and material choices, you can make sure your 3D prints are high quality and look great on display—no matter what they contain.